108605

论文已发表

注册即可获取德孚的最新动态

IF 收录期刊

- 3.4 Breast Cancer (Dove Med Press)

- 3.2 Clin Epidemiol

- 2.6 Cancer Manag Res

- 2.9 Infect Drug Resist

- 3.7 Clin Interv Aging

- 5.1 Drug Des Dev Ther

- 3.1 Int J Chronic Obstr

- 6.6 Int J Nanomed

- 2.6 Int J Women's Health

- 2.9 Neuropsych Dis Treat

- 2.8 OncoTargets Ther

- 2.0 Patient Prefer Adher

- 2.2 Ther Clin Risk Manag

- 2.5 J Pain Res

- 3.0 Diabet Metab Synd Ob

- 3.2 Psychol Res Behav Ma

- 3.4 Nat Sci Sleep

- 1.8 Pharmgenomics Pers Med

- 2.0 Risk Manag Healthc Policy

- 4.1 J Inflamm Res

- 2.0 Int J Gen Med

- 3.4 J Hepatocell Carcinoma

- 3.0 J Asthma Allergy

- 2.2 Clin Cosmet Investig Dermatol

- 2.4 J Multidiscip Healthc

在 E-jet 3D 打印平台上生长的成肌细胞的生长和分化增强

Authors Chen H, Zhong J, Wang J, Huang R, Qiao X, Wang H, Tan Z

Received 6 November 2018

Accepted for publication 8 January 2019

Published 4 February 2019 Volume 2019:14 Pages 937—950

DOI https://doi.org/10.2147/IJN.S193624

Checked for plagiarism Yes

Review by Single-blind

Peer reviewers approved by Dr Alexander Kharlamov

Peer reviewer comments 2

Editor who approved publication: Dr Linlin Sun

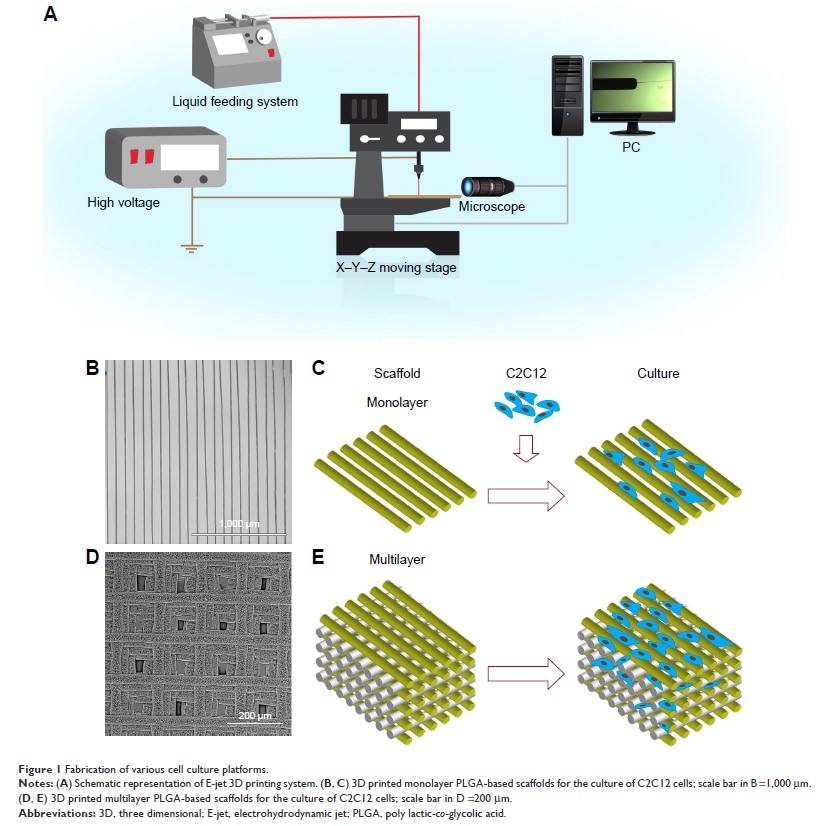

Background: Skeletal

muscle tissue engineering often involves the prefabrication of muscle tissues

in vitro by differentiation and maturation of muscle precursor cells on a

platform which provides an environment that facilitates the myogenic

differentiation of the seeded cells.

Methods: Poly

lactic-co-glycolic acid (PLGA) 3D printed scaffolds, which simulate the highly

complex structure of extracellular matrix (ECM), were fabricated by E-jet 3D

printing in this study. The scaffolds were used as platforms, providing

environment that aids in growth, differentiation and other properties of C2C12

myoblast cells.

Results: The C2C12

myoblast cells grown on the PLGA 3D printed platforms had enhanced cell

adhesion and proliferation. Moreover, the platforms were able to induce

myogenic differentiation of the myoblast cells by promoting the formation of

myotubes and up-regulating the expressions of myogenic genes (MyHC and MyOG).

Conclusion: The

fabricated 3D printed platforms have excellent biocompatibility, thereby can

potentially be used as functional cell culture platforms in skeletal tissue

engineering and regeneration.

Keywords: myoblast,

myogenic differentiation, 3D printing, 3D cell culture, skeletal muscle

regeneration