108605

论文已发表

注册即可获取德孚的最新动态

IF 收录期刊

- 3.4 Breast Cancer (Dove Med Press)

- 3.2 Clin Epidemiol

- 2.6 Cancer Manag Res

- 2.9 Infect Drug Resist

- 3.7 Clin Interv Aging

- 5.1 Drug Des Dev Ther

- 3.1 Int J Chronic Obstr

- 6.6 Int J Nanomed

- 2.6 Int J Women's Health

- 2.9 Neuropsych Dis Treat

- 2.8 OncoTargets Ther

- 2.0 Patient Prefer Adher

- 2.2 Ther Clin Risk Manag

- 2.5 J Pain Res

- 3.0 Diabet Metab Synd Ob

- 3.2 Psychol Res Behav Ma

- 3.4 Nat Sci Sleep

- 1.8 Pharmgenomics Pers Med

- 2.0 Risk Manag Healthc Policy

- 4.1 J Inflamm Res

- 2.0 Int J Gen Med

- 3.4 J Hepatocell Carcinoma

- 3.0 J Asthma Allergy

- 2.2 Clin Cosmet Investig Dermatol

- 2.4 J Multidiscip Healthc

3D 打印介孔生物玻璃/麦醇溶蛋白/聚己内酯三元复合物支架可增强抗压强度、降解性、细胞反应和促进新骨组织向内生长

Authors Zhang Y, Yu W, Ba Z, Cui S, Wei J, Li H

Received 7 February 2018

Accepted for publication 3 July 2018

Published 17 September 2018 Volume 2018:13 Pages 5433—5447

DOI https://doi.org/10.2147/IJN.S164869

Checked for plagiarism Yes

Review by Single-blind

Peer reviewers approved by Dr Colin Mak

Peer reviewer comments 3

Editor who approved publication: Dr Linlin Sun

Background: Due to the increasing number of patients with bone defects, bone

nonunion and osteomyelitis, tumor and congenital diseases, bone repair has

become an urgent problem to be solved.

Methods: In this study, the 3D-printed scaffolds of ternary composites

containing mesoporous bioglass fibers of magnesium calcium silicate (mMCS),

gliadin (GA) and polycaprolactone (PCL) were fabricated using a 3D Bioprinter.

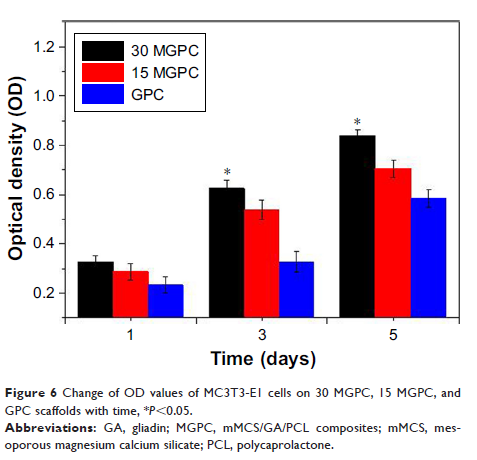

Results: The compressive strength and in vitro degradability of the

mMCS/GA/PCL composites (MGPC) scaffolds were improved with the increase of mMCS

content. In addition, the attachment and proliferation of MC3T3-E1 cells on the

scaffolds were significantly promoted with the increase of mMCS content.

Moreover, the cells with normal phenotype attached and spread well on the

scaffolds surfaces, indicating good cytocompatibility. The scaffolds were

implanted into the femur defects of rabbits, and the results demonstrated that

the scaffold containing mMCS stimulated new bone formation and ingrowth into

the scaffolds through scaffolds degradation in vivo. Moreover, the expression

of type I collagen into scaffolds was enhanced with the increase of mMCS

content.

Conclusion: The 3D-printed MGPC scaffold with controllable architecture, good

biocompatibility, high compressive strength, proper degradability and excellent

in vivo osteogenesis has great potential for bone regeneration.

Keywords: ternary composites, polymer-based composite, biocompatibility,

cytocompatibility, osteogenesis